Cranston, September 2019. For over 3 decades, the Yushin organization has worked tirelessly to offer the most advanced, reliable and easy to use robotics to the injection molding industry. Today, Yushin is pleased to be launching a new line of large full-servo traverse robots that automate extraction of large, heavy molded parts used in the Appliance, Automotive and Industrial Construction industries.

The MKA-2000S, a 3-axis Cartesian style traverse robot, which features a movable kick beam and a 2-stage telescopic vertical arm. The long rigid, steel traverse beam that offers reliable and stable control is adjustable up to 5000mm, with a horizontal reach of 1800mm. The 2-stage telescopic arm has vertical strokes of up to 3000mm. The MKA-2000S robot works on molding machines of 1500 tonnage or larger and can also handle loads of 30kg up to 50 kg with the inclusion of End-of-arm tooling. The MKA robot comes with a wide list of optional equipment and features to choose from to help you optimally complete your downstream process.

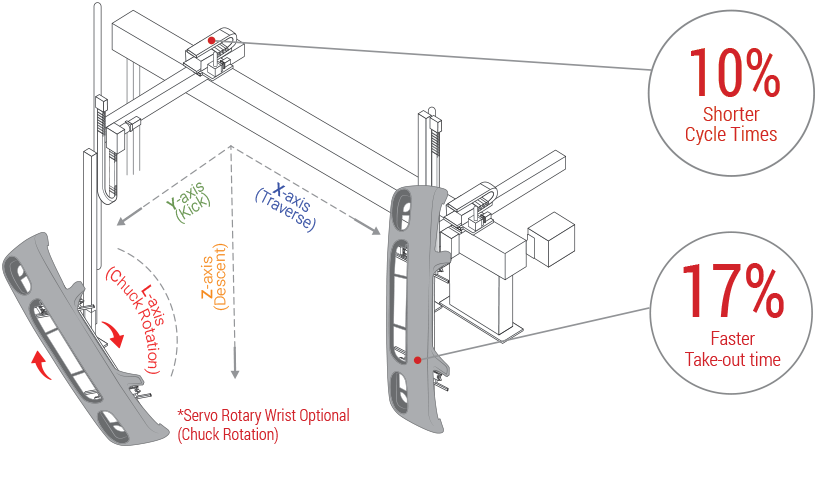

A servo AC or BC wrist unit can be added to the arm wrist as an option, enabling precision control and motion comparable to an articulated 6-axis robot. The MKA-2000S has been tested and proven to exceed its previous larger counterparts like the RBII-2500S with shorter take-out times by 17%. It’s superior vibration damping during movement and stops helps ensure stable and shorter cycle times by 10% (Figure 1.). The low profile design of the MKA allows for work envelopes with lower overhead clearance that efficiently saves space on production floor.

Figure 1. Illustration shows Movable Kick Beam with Large Automotive bumper

The MKA is equipped with the user-friendly, E-touch Compact (Figure 2) controller featuring a highly visible 7.5 full-color touchscreen. This controller is loaded with convenient new functions, such as synchronous cooperative axes of motion, including full integration with auxiliary downstream equipment. Each axis can be programmed to function independently or in combination of axes. Conveniently monitor robot operations and alert operators with a message if potential symptoms are detected. Simply open the flowchart screen to check conditions quickly and speed up troubleshooting. This function elevates maintenance from preventative to predictive, helping to save time and programming costs.

Figure 2. E-touch Compact Controller

Yushin introduced the MKA robot to accommodate companies molding large and heavy products. Yushin will continue to build automation products that will help solve challenges facing in plastic industries. As a result, Yushin continues to refine their products to different heights and directions and constantly offers something new to adapt to the new challenges. To learn more about the new MKA-2000S series, contact us at [email protected].

For more information about the MKA-2000S robot, visit our MKA-2000S product page

# # #

About Yushin America, Inc.

Yushin America, Inc., headquartered in Rhode Island, is known worldwide for their expertise in robotics for the plastics industry. They offer a wide range of automation technology, ranging from individual robots for parts removal, to fully integrated factory automation for assembly, decoration, inspection and packaging. They also provide end-of-arm tool design, conveyors, service and training. Yushin America, Inc. is the largest subsidiary company of Yushin Precision Equipment Co. Ltd of Japan, one of the world’s largest suppliers of robots for the injection molding industry. For more information about Yushin robots and our molding automation technology offerings, please visit our web site at www.yushinamerica.com or contact Yushin America, Inc., 35 Kenney Drive, Cranston, RI 02920.

Leave A Comment