Our Systems and Applications

Systems Integration and Full Factory Automation

YAI principally combines Yushin Precision Equipment’s excellence in product development with an unbeatable standard of application engineering and system integration to provide complete product automation to injection molding processes. Solutions can range from basic semi-automatic equipment to fully automated cells with multiple pieces of automation combined. We have experience in many facets of automation including part and sprue removal, part assembly, product inspection, bagging, box loading, palletizing, and conveyor systems.

If you have an application that requires end-of-arm tooling, send us your video or photos of your application and we will send you feedback immediately. Feel free to contact us so we can review the project details and discuss tooling options!

Full Downstream Automation Systems Collection:

Yushin America has been showcasing numerous Downstream Automation capabilities at the National Plastics Expo in Orlando, FL.

Contact us today to set up a consultation with one of our Yushin Experts.

Speed, Precision and Efficiency

Known for their speed, precision and production efficiency, Yushin robots supports a variety of Complex Automated Systems to efficiently handle customer parts throughout the entire process.

Our engineering team has extensive automation experience and works closely with customers to provide the most effective solution based on their requirements. Our methodical process helps reduce the risks associated with implementing automation based on many factors that may impact the project.

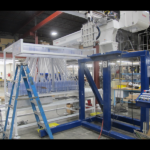

Our systems are designed, fabricated, tested, and run-off at our Cranston, RI facility by our team of highly skilled engineers and automation technicians. We have an in-house machine shop that runs two shifts to product the complex components for end-of-arm tooling and automation projects. We have a weld shop and a paint shop to fabricate the frames and components for the equipment we supply.

Contact your nearest Sales Representative today to discuss the right solutions to your automation.

*Downstream systems may require a service person and an engineer to visit your facility and start up the system.

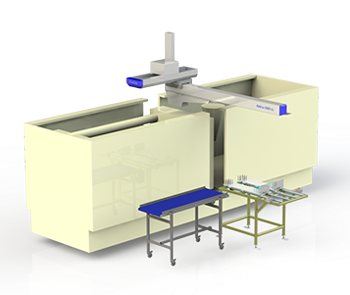

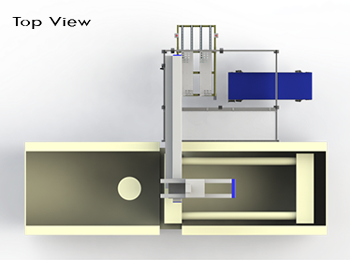

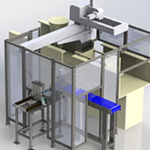

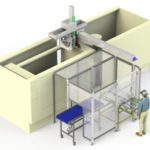

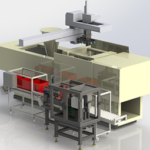

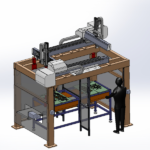

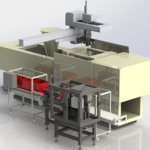

Below are sample renderings of molding cells including – IMM, Yushin Robot,Safety Guarding, End-Of-Arm Tooling, Conveyor, and required auxiliary equipment to support a complete downstream automation. Contact us for more information.

Yushin America exhibited at NPE2018 and showcased a complete downstream automation of producing a Shaker Cup and Shaker Lid with Custom 2 cavity Unscrew EOAT with Hot Stamp & In-Mold Labeling finish. The finished shaker cup was picked up by a collaborative robot – OB7 and placed onto the conveyor. Watch the downstream automation here:

- Closing gantry style station w/ vision inspection

- 38 & 45 mm Cap Closing station

- Insert EOAT with bowl feeder and cooling

- Pallet Loading Station

- Custom Downstream Automation

- YC – Floor mounted Pack out Application

- Yushin Robot, IMM, Insert Label Station, Guarding, Conveyor

- Yushin Robot, IMM, Safety Guarding, Conveyor, Operator

- Yushin Robot, IMM, Bowl Feeder, Box loading conveyor (Guarding not shown)

- Integrated Automated Cell – Yushin Robot, IMM, Safety Guarding, Rotating Conveyor

- Two standard robots with servo wrists to cut 60 gates mounted on a frame with light curtains.

- Closing Gantry Style Station

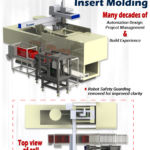

Systems designed for Insert Molding Applications

Yushin has successfully completed hundreds of insert end-of-arm tooling projects over the years. Our team can guide you through the process of implementing an insert end-of-arm tool from the beginning by giving input for the mold design, assisting with mold recommendations, making recommendations on insert design and best methods for handling inserts.

There are many options when it comes to insert molding that range from semi-automatic to completely automated projects. Depending upon the benefit to your organization, we will help find the fit for your application.

- Custom Insert Molding Application

- Insert Load-Unload Station System

- Manual Slit Station

- Insert Loading Finished part Return Station and a Pre-heating Station

- 4-cavity Insert EOAT with Magnet feed Maganize Station

Engineering Cut Sheets:

- Two Bay Insert Molding pg1

- Two Bay Insert Molding pg2

- Full Bowl Feeder Insert Molding pg1

- Two Bay Insert Molding pg2

- Box Loading Conveyor

- Box Loading Conveyor

- CAD drawing

- Box Loading conveyor with Chute

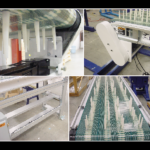

- Belt Fabric Conveyor

- Cooling-Conveyor-System

- Over/under conveyor 1

- Over/under conveyor 2

- Vial loading on a pin conveyor

- Tray Load stack/destack System – Plastic trays being loaded. Pitch revise, stack / destack, transfer.

- Tray Load Conveyor – Loading trays with an SXC-40 robot, inspecting parts

- Pin Loading Conveyor

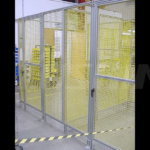

Safety Guarding Systems

Guarding allows the operator to access the IMM control panel and safety gate while protecting the robot work envelope. Panels can be configured with interlocked access doors and conveyor cut-outs. Guarding can be manufactured with interlocked access doors and conveyor cut-outs.

Optional choice for Guarding:

- Operator Side Discharge Guarding

- Rear Side Discharge Guarding

- Custom Guarding

Take a look at some of our Safety Guardings that have been fabricated and built for our customers.

- Custom Safety Guarding – Yellow mesh

- Custom Safety Guarding – Yellow mesh

- Custom Safety Guarding – Black mesh

- Custom Safety Guarding with chute & frame

- Custom Safety Guarding

- Custom Safety Guarding

- Custom Safety Guarding with E-stop

Downstream Automation

Known for their speed, precision and production efficiency, Yushin robots supports a variety of Complex Automated Systems to efficiently handle Insert Molding, Vision Inspection, In Mold Labeling (IML), Stock systems, Assembly applications to custom turn-key solutions to your downstream automation.

Our automation capabilities include an in-house machine shop where we design and build downstream automation, fixtures & nests, end of arm tooling and guarding. Yushin’s Engineering department specilizes in downstream automation for handling your parts for Inspection, Assembly, Packing, and other operations. All designed and built in-house.

Contact your nearest Sales Representative today to discuss the right solutions to your automation.

Downstream systems may require a service person and an engineer to visit your facility and start up the system.

*Samples to follow

Insert Molding Application

Insert Molding is when plastic is injected into the mold cavity and insert piece (or pieces) prior to plastic injection molding. The resulting product is a single piece with the insert encapsulated by the plastic.

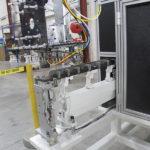

Insert Molding EOATs for Plastics Injection Molds is a difficult tasks for either an operator or EOAT to perform. Our dedicated Engineers are ready at hand to tackle any situation and design the perfect End-Of-Arm Tool for your Insert Molding application.

Sample Renderings:

Two-bay station Insert Molding