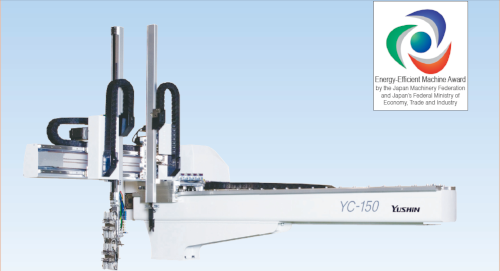

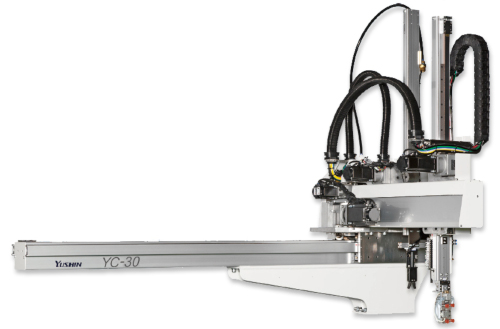

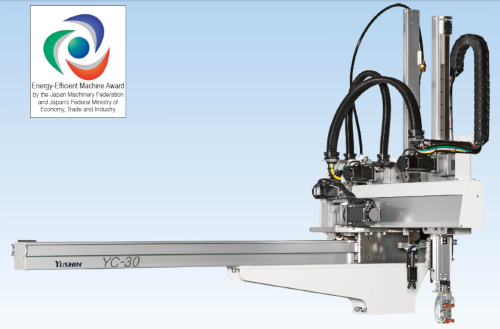

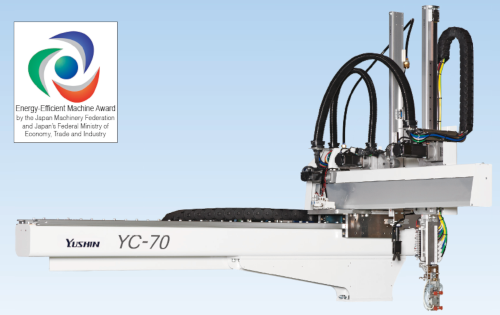

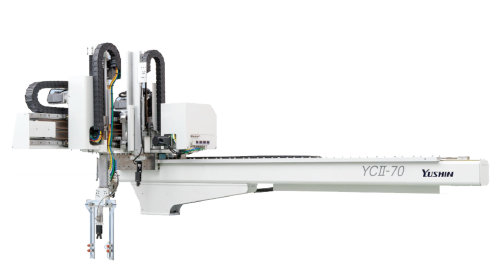

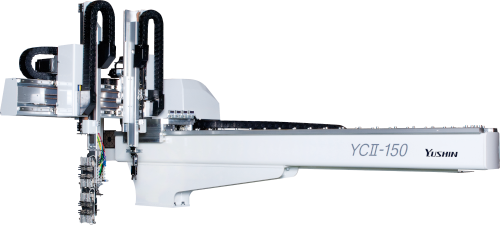

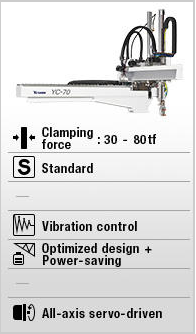

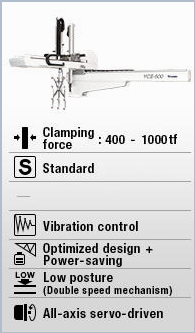

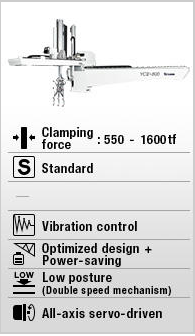

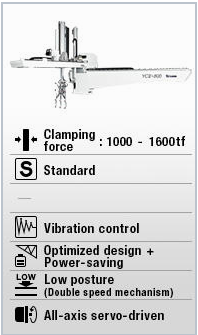

Optimally designed to conserve energy, air consumption and reduce settling times

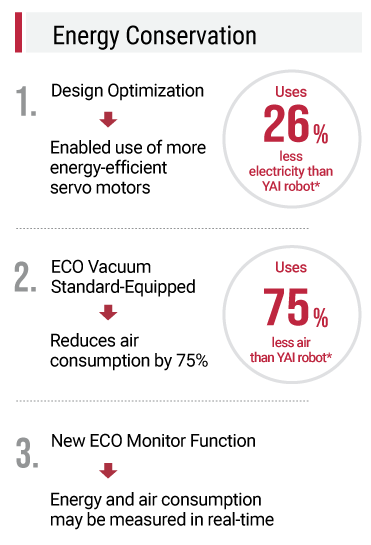

Optimally designed through the joint research with Kyoto University. Optimum Design is what Yushin calls the application of CAE (Computer—Aided Engineering) to determine the most theoretically optimal configuration of a robot based on its mechanisms and movements. This advanced approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Yushin applied this approach to reduce the weight and control the vibrations of the YC/YCII series. As a result, power consumption and settling time have been respectively reduced by 26% and 72%, which puts users in position to improve their productivity.

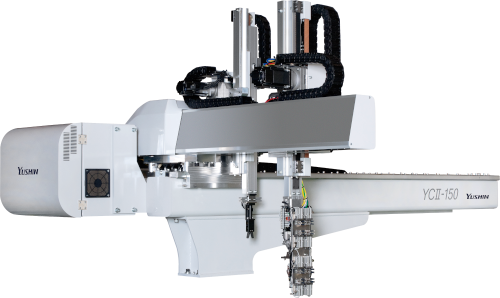

Winner of the JSME Technology Award

In 2011, Yushin was honored with the prestigious Technology Award of the Japan Society of Mechanical Engineers (JSME) for “developing high-performance take-out robots for molding machines by structural optimization”. Click here for the Award: Development of high-performance take-out robots for injection molding machines using a structural optimization method

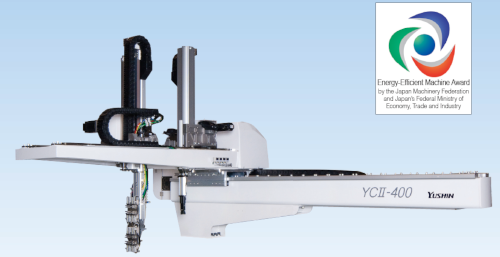

Winner of the JMF President’s Award for Energy Efficiency

In 2011, Yushin’s YC series of take-out robots for injection molding machine was recognized by the Japan Machinery Federation (JMF) with the JMF President’s Award at their Energy Efficient Machine Awards for the air consumption and weight reductions achieved through Optimum Design.