Why is a several hundred kilogram robot needed to pick a molded part of just a few grams?

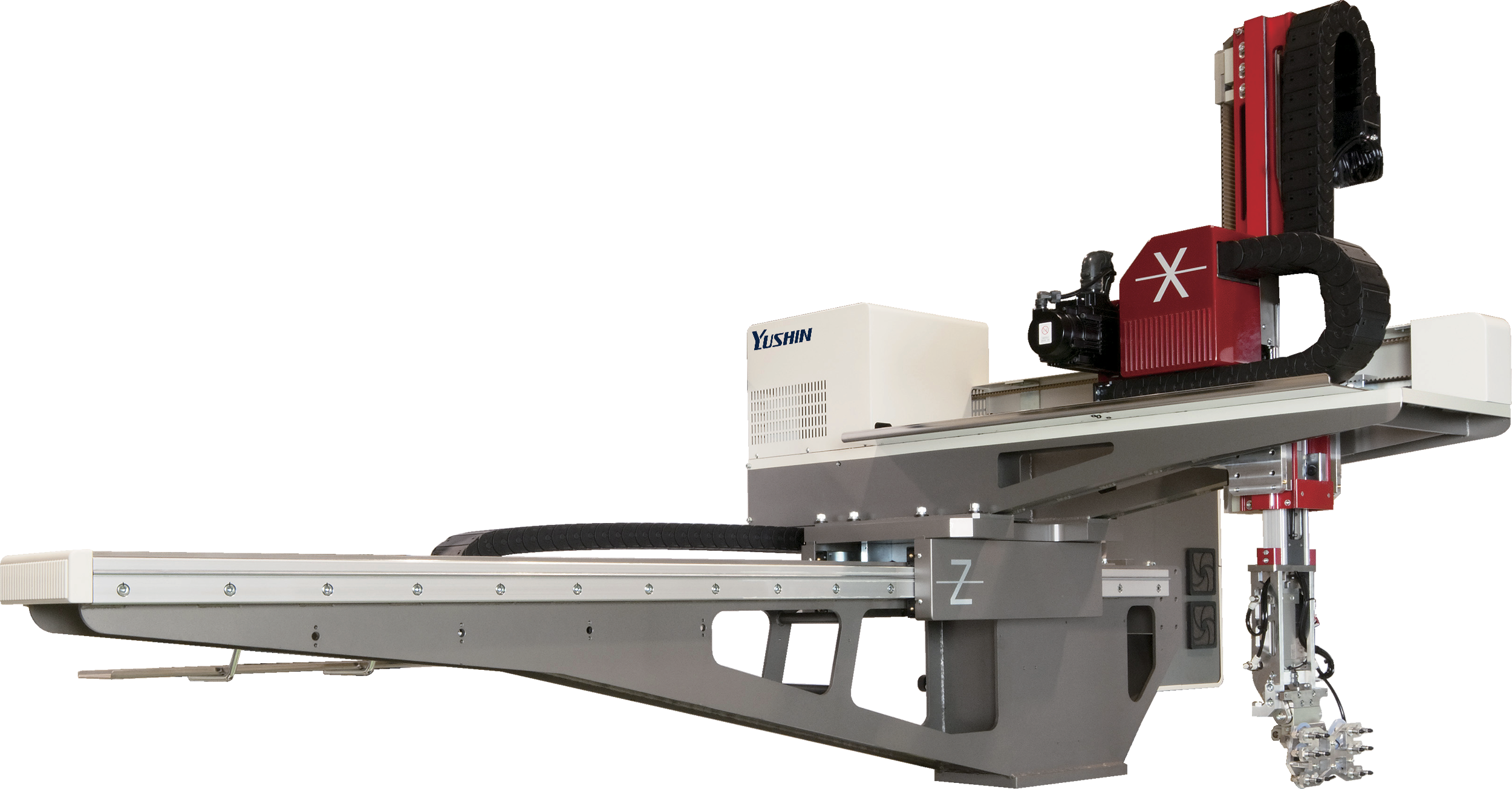

To answer this question, Yushin sought an application-specific robot through its Optimum Design approach. Design Optimization is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements, rather than relying solely on designer experience. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Curiously enough, we have often been amazed by how closely optimized designs resemble trees and animals in the natural world. Designed to deliver speeds and safety unachievable with predecessor models, we are confident that the HSA series will usher in a new era in take-out robots.

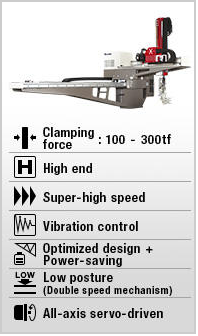

The HSA incorporates Design Optimization for higher speed and rigidity with less weight. With take-out times as fast as 0.32 sec proven during live molding, the HSA is 13% lighter and 11% faster than previous models (measurements are relative to previous comparable model).