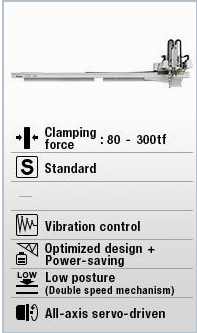

Features

Conveyor belt centralization

Separate conveyor belts are not needed for each molding machine, therefore centralized processing can be used for packaging or inspecting molded parts.

26% less power consumed than by predecessor robots

Because robot weight reduces by applying Optimum Design approach, lower duty motors are used.

75% less air consumed than by predecessor robots

Air consumption has been reduced by 75% from predecessor models by incorporating Yushin’s propriety ECO Vacuum circuit as a standard feature.

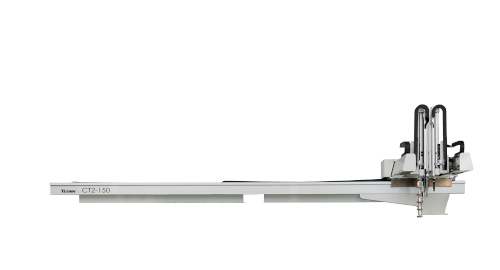

Design

Space-efficient

Because the space between molding machines can be narrowed, more machines can be installed

From runner take-out to product take-out

Additional space is not required to replace an existing runner take-out robot with either the CT or CT2 product take-out robot.

72% shorter settling time than predecessor robots

With the CT and CT2 series, Optimum Design, CFRP and anti-vibration controls combine to shorten settling time (time required for vibrations to fall below a desired level) by 72%, which naturally shortens the full molding cycle.

Because the space between molding machines can be narrowed, more machines can be installed