Where Molding & Moldmaking Innovation Takes Shape

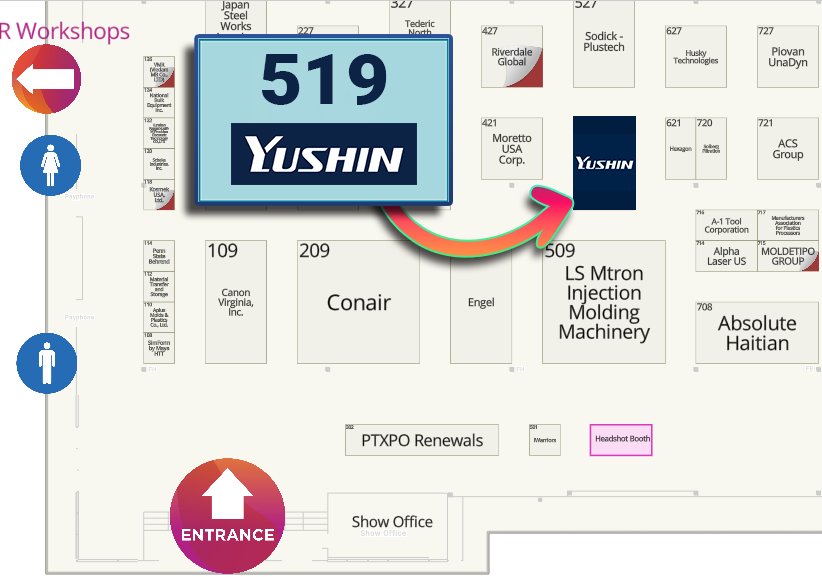

We are excited once again to be exhibiting at the Donald E. Stephen center for the PTXPO 2025 event! Yushin America will be in BOOTH#519 to deliver this fully functioning automation cell that will showcase our products and capabilities. Come by and learn about our products and solutions that can help with your next automation project!

Learn more about the event here

We’re thrilled to offer you FREE Exhibit Hall admission to the Plastics Technology Expo (PTXPO) taking place March 18-20, 2025, at the Donald E. Stephens Convention Center in Rosemont, IL, near Chicago.

PTXPO is your one-stop shop for everything in the molding and moldmaking industry. Explore a vast exhibit hall showcasing the latest injection molders, mold makers, 3D printing, auxiliary equipment manufacturers, materials producers, and recycling specialists. Witness equipment demonstrations firsthand and gain valuable insights from educational sessions offered in the Discovery Workshops and Tech Talk Theaters.

PTXPO25 is an unmissable opportunity to:

- Network with key industry players from across North America.

- Discover groundbreaking applications and products shaping the future of molding and moldmaking.

- Learn cutting-edge processes and best practices to fuel your success.

Be sure to stop by and visit us at our display in Booth #519 so we can personally welcome you and see how we can serve your business.

PTXPO 2025 Exhibit Hall Hours

Tuesday, March 18th, 10:00 am – 4:00 pm

Wednesday, March 19th, 9:00 am – 4:00 pm

Thursday, March 20th, 9:00 am – 3:00 pm

Registration is quick, easy, & FREE!

- Click here and use the special pre-populated code to register for your free Exhibit Hall pass!

- You may also pass along to as many team members as you’d like!

For more information, please visit: www.ptxpo.com

We look forward to seeing you in Rosemont!

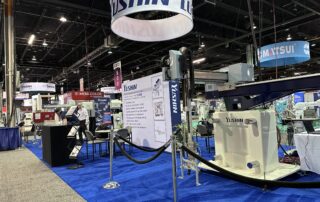

We have new robots showcasing our capabilities

Experience Innovation at PTXPO 2025!

Join us at Booth 519 for a firsthand look at the latest advancements in plastics molding technology. Discover cutting-edge solutions designed to enhance efficiency and productivity on your production floor.

Our expert automation team will be on hand to answer your questions and help you find the right products and solutions to meet your project needs. Don’t miss this opportunity to explore innovations that can transform your molding processes!

The RC-SE Series is engineered for molding machines with clamping forces ranging from 30 to 1,300 tons. Featuring Yushin’s ECO Vacuum technology, it optimizes efficiency by reducing air consumption by up to 78% through continuous suction pressure monitoring. This innovation not only minimizes electricity usage but also lowers operational costs associated with air compressors.

The new YD Series take-out robots build upon the expertise of earlier models to deliver higher productivity, reduced downtime, and a smaller environmental footprint. Designed for injection molding machines ranging from 30 to 1,500 tons, the YD Series features carbon-fiber reinforced components, enhancing performance and durability. The use of advanced composites results in a 46% increase in flexural rigidity and a 13% reduction in single-arm vibration amplitude compared to previous models, ensuring greater precision and efficiency.

WEMO 12 XLine Series

The xDesign series is engineered for a wide range of applications, including the molding of technical parts requiring complex automation.

This versatile robot series can be equipped with servo-driven rotation axes and has the capability to control external axes, providing enhanced flexibility and precision for advanced molding processes.

WEMO 3-5 Linear Picker

Its compact, space-saving design allows for seamless integration within robot guarding, eliminating the need for additional floor-mounted safety barriers. This streamlined setup enables easier and faster installation, optimizing workspace efficiency.

Leave A Comment