Our EOAT

End-Of-Arm Tools

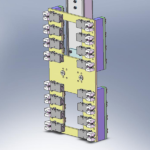

End-of-arm tools require accuracy, repeatability and durability, and they have to be easy to maintain and optimally designed to be lightweight so as to attain fast speeds. Yushin has taken out virtually every kind of part imaginable under varying degrees of difficulty and puts the know-how born from that into tailoring user needs into the best solutions for them.

End-of-arm tooling experts will evaluate your project and determine the best solution for your application. We have a staff of engineers with experience in all facets of tooling design ranging from insert applications to multi-robot systems that require no operator interface.

For any and all of our EOAT tooling, check out the tabs below! If you have any further questions, feel free to reach out to us today!

Our strong yet lightweight EOATs allow faster take-out cycle times and shorter tool settling times. For many applications the tooling mass can be reduced by as much as 40% and reduce cycle times by up to 10%. We can also offer a modular adjustable kit that can be adapted to run on more than one tool. Where necessary, detection of missing parts can be performed by vacuum, cylinder switch, part sensor or fibre optics.

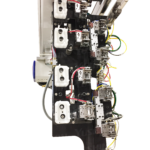

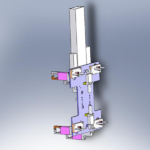

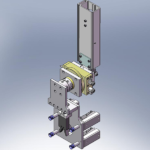

- 4 Cavity Terminal Insert-EOAT

- Insert EOAT

- Insert EOAT

- Insert Load Station EOAT

- Two bay Insert EOAT

- Dual Function Insert Molding EOAT

- Semi Auto Insert EOAT

We have designed hundreds of end-of-arm tools with a variety of functions. Our EOAT’s range from basic adjustable tooling to complex multi-function inserting applications. Let our engineers provide you with the best possible solution for your EOAT needs.

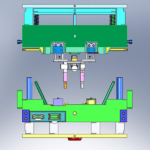

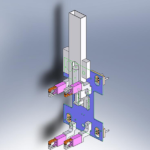

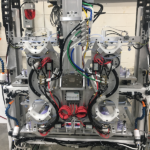

- 4 Cavity IML EOAT

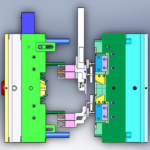

- 4 Cavity Wrap IML EOAT – front

- 4 Cavity Wrap IML EOAT – back

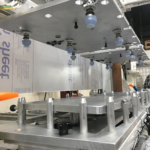

- Label Station

- Label Station

- Label Station

- Label & Pick IML EOAT

End-of-arm tooling experts will evaluate your project and determine the best solution for your application. We have a staff of engineers with experience in all facets of tooling design ranging from insert applications to multi-robot systems that require no operator interface. With extensive robotic automation experience for the manufacturing industry, our engineers conceptually design dynamic and advanced tools, utilizing State of the Art 3D CAD tools from custom special EOAT to standard tooling.

Here are some sample EOAT tools

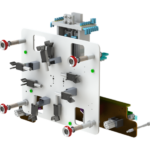

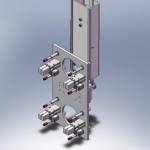

- Custom Insert Molding Application

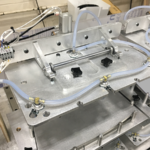

- 64 cavity with venturi and sensors mounted on EOAT

- 38 & 45 mm cap closing station

Insert Molding

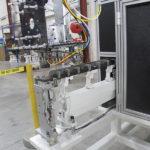

Two Bay Station – Dual Function Insert Molding EOAT

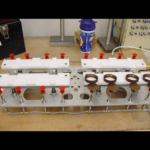

In Mold Labeling EOAT

In Mold Labeling (IML) for injection molding means that the decoration of the product takes place in the mold. An IML label is inserted into the mold. During the injection process, the injected molten polymer fuses with the in mold label. The end result is a decorated packaging part, produced in one step.

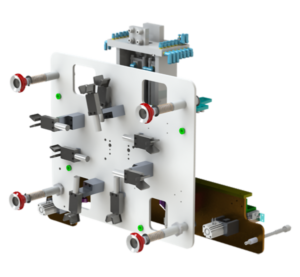

Special / Custom EOAT

Yushin America provides custom or special End-Of-Arm-Tooling (EOAT) for any downstream automation needs.