Our Services

Yushin America’s Services

For any and all of our services, check out the tabs below! If you have any further questions, feel free to reach out to us today!

Installations, repairs, and periodic maintenance

Yushin has a team of certified technicians across the country ready to help you when you need it. They can assist you with new installations; asset relocations from other facilities; robot modifications; and trouble calls. Get the most out of your equipment. Have a Yushin field service tech come in to perform a preventative maintenance routine or upgrade your equipment. Our technicians can also take care of on-site training needs.

Yushin America offers customer support and service from our headquarters in Rhode Island and through branch service offices in:

| Cranston, RI | Corona, CA |

| Columbus, OH | San Antonio, TX |

| Bolingbrook, IL | St. Charles, IL |

| Downers Grove, IL | Bath, MI |

| Atlanta, GA | Asheville, NC |

| Leon, Guanajuato, MX |

YAI’s field service staff enables the company to provide efficient and low-cost installations and service as well as a quick and timely response to customer needs in general. Yushin engineers frequently visit customer facilities as part of the applications engineering and specification process. YAI offers preventative maintenance and service contracts and provides ongoing application assistance for changing customer needs regarding tooling, software and downstream equipment integration.

Click here to search for a Certified Yushin Service Technician near you!

General Rates for Installation, Startup, and Service

Monday through Friday:

$1,200 per 8-hour day

Up to 4 hours is considered a half day and will be invoiced at $600.00

Up to 8 hours is considered a full day and will be invoiced at $1,200.00

Over the 8-hour work day will be invoiced at $225.00 per hour

Weekends and Holidays:

Up to 4 hours is considered a half day and will be invoiced at $1,200.00

Up to 8 hours is considered a full day and will be invoiced at $2,400.00

Over the 8-hour work day will be invoiced at $450.00 per hour

Inclusive of basic machine operation training

Inclusive of travel time, travel expenses and living expenses (airfare is not included)

Door-to-door travel time between YAI’s facility and the customer’s facility is chargeable at the rates shown above.

Rigging and mounting of the robot(s) is the customer’s responsibility and is not included in the rates above.

This installation estimate assumes that the robot(s) will be mounted prior to our visit.

Pricing is subject to change without notice.

To schedule a service visit, please contact:

webservice@yushin.com

Tel: (401) 463-1800, choose option 2 or enter Extension 3395

Dir: (401) 490-4972

Fax: (401) 463-1814

Your questions answered, 24/7

Whether you need a replacement manual or have a machine down, our team of dedicated technical service engineers is available to help with immediate issues over the phone or via email, supported by on-site service visits when necessary. Telephone support for Yushin equipment is available 24 hours a day, 7 days a week.

Please contact our Rhode Island headquarters (Eastern time zone) for support. For after-hours support, please use our Service Support Hotline.

For technical support, please contact:

webservice@yushin.com

Tel: (401) 463-1800, choose option 2 or enter Extension 3395

Dir: (401) 490-4972

Fax: (401) 463-1814

After-hours Service Support Hotline:

Toll-free (888) 707-6268

Or (888) 70-ROBOT

Or (401) 463-8398

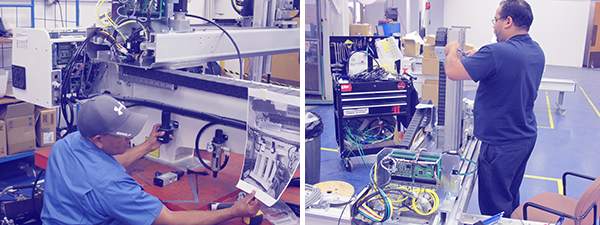

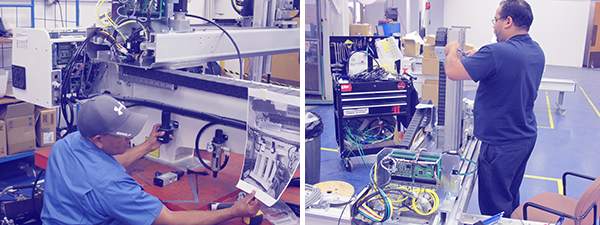

Yushin Technicians with Repair work

Installations, repairs, and periodic maintenance

Yushin America offers customer support and service from our headquarters in Rhode Island and through branch service offices in:

| Cranston, RI | Corona, CA |

| Columbus, OH | San Antonio, TX |

| Bolingbrook, IL | St. Charles, IL |

| Downers Grove, IL | Bath, MI |

| Atlanta, GA | Asheville, NC |

| Leon, Guanajuato, Mexico |

YAI’s field service staff enables the company to provide efficient and low cost installations and service as well as quick and timely response to customer needs in general. Yushin engineers frequently visit customer facilities as part of the applications engineering and specification process. YAI offers preventative maintenance and service contracts and provides ongoing application assistance for changing customer needs regarding tooling, software and downstream equipment integration.

Click here to search for a Certified Yushin Service Technician near you!

General Rates for Installation, Start up and Service

Monday through Friday:

$1,000 per 8-hour day

Up to 4 hours is considered a half day and will be invoiced at $500.00

Up to 8 hours is considered a full day and will be invoiced at $1,000.00

Over the 8-hour work day will be invoiced at $187.50 per hour

Weekends and Holidays:

Up to 4 hours is considered a half day and will be invoiced at $1,000.00

Up to 8 hours is considered a full day and will be invoiced at $2,000.00

Over the 8-hour work day will be invoiced at $250.00 per hour

Inclusive of basic machine operation training

Inclusive of travel time, travel expenses and living expenses (airfare is not included)

Door-to-door travel time between YAI’s facility and the customer’s facility is chargeable at the rates shown above.

Rigging and mounting of the robot(s) is the customer’s responsibility and is not included in the rates above.

This installation estimate assumes that the robot(s) will be mounted prior to our visit.

Pricing is subject to change without notice.

To schedule a service visit, please contact:

webservice@yushin.com

Tel: (401) 463-1800, choose option 2 or enter Extension 3395

Dir: (401) 490-4972

Fax: (401) 463-1814

Your questions answered, 24/7

Whether you need a replacement manual or have a machine down, our team of dedicated technical service engineers is available to help with immediate issues over the phone or via email, supported by on-site service visits when necessary. Telephone support for Yushin equipment is available 24 hours a day, 7 days a week.

Please contact our Rhode Island headquarters (Eastern time zone) for support. For after-hours support, please use our Service Support Hotline.

For technical support, please contact:

webservice@yushin.com

Tel: (401) 463-1800, choose option 2 or enter Extension 3395

Dir: (401) 490-4972

Fax: (401) 463-1814

After-hours Service Support Hotline:

Toll-free (888) 707-6268

Or (888) 70-ROBOT

Or (401) 463-8398

Yushin Technicians with Repair work