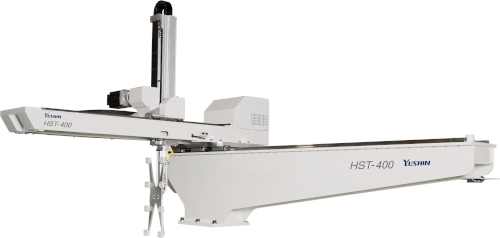

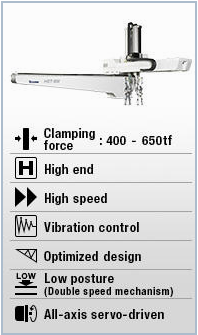

Improved productivity via high speed + vibration control

HST robots bring to the table the tools and means for improving productivity in the form of high-speed operation and thorough vibration controls. Higher speeds have been achieved by employing Optimum Design approach to reduce the mass of moving parts, while the enhanced vibration dampening of the CFRP arm combines with anti-vibration measures to shorten settling time.

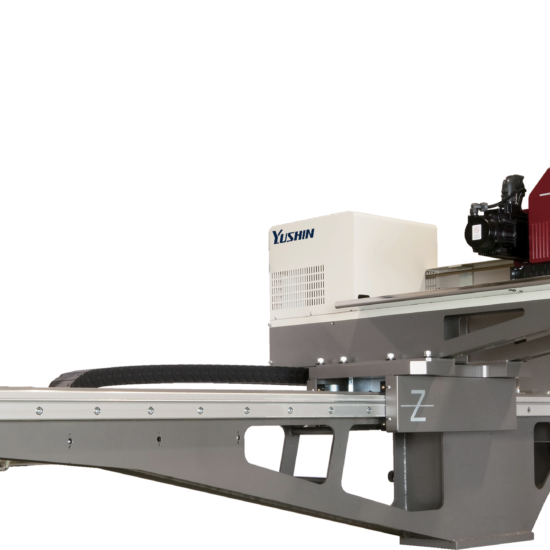

Optimum Design

Joint research with Kyoto University

Optimum Design is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Through joint research conducted with Kyoto University, Yushin first tested and applied CAE to an EOAT. Following the good results, this Optimum Design approach was employed with take-out robots of the HSA, TSXA, YC and HST series.

Winner of the JSME Technology Award

Great reviews in engineering circles

In 2011, Yushin was honored with the prestigious Technology Award of the Japan Society of Mechanical Engineers (JSME) for “developing high-performance take-out robots for molding machines by structural optimization”.